A photovoltaic system is a system for the production of electrical energy. Photovoltaic technology allows to directly convert solar energy incident on the earth's surface into electricity, using the properties of some semiconductor materials. Photovoltaic systems are generally divided into two categories: stand-alone systems, and grid-connected systems.

The costs of the implementation are currently strong decrease thanks to the diffusion that this technology is having for the effect of government incentives of deduction of 50%. By accessing the system and the additional mechanism of "metering" if you decide to use this technology you will benefit from the following economic advantages:

1. the energy produced in excess of your consumption will be valued at the market price;

2. the energy consumed during periods when your system is in production will avoid to draw power from the grid.

How does the photovoltaic system works

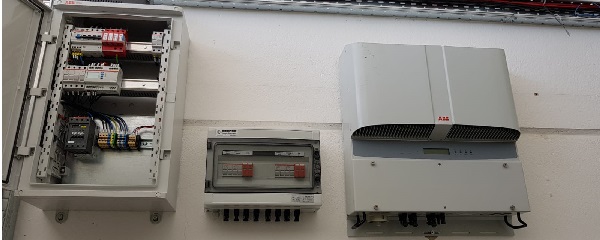

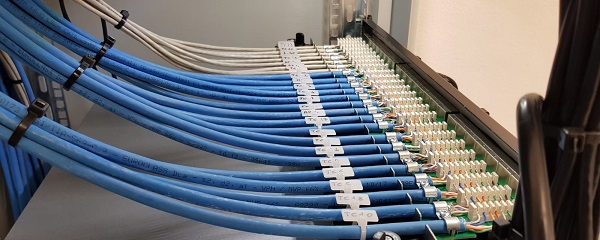

The working of photovoltaic devices is based on the ability of some semiconductor materials, properly treated, to convert solar energy into electrical energy (current). One of these is silicon, whose molecular structure can be monocrystalline or polycrystalline. The monocrystalline silicon cells provide the best of outcome, but the process of production has a considerable weight on the costs. The polycrystalline silicon, however, is cheaper but yields slightly lower. More cells joined together forms photovoltaic panels (or modules). As regards the installation, in the case of plants places on the ground or on flat roof, the panels are usually distributed on multiple files, spaced apart in a regular manner and inclined towards the sun. The electricity produced is normally low voltage and direct current (DC); then to be used it is necessary to transform it into alternating current (AC): this is achieved thanks to a device called inverter. Then, to implement a system of this type (in addition to cables, electrical panels, switches, and other devices) will be needed photovoltaic modules, the inverter and a counter. Of course, all systems must be connected to the local electricity network. So when you don't produce energy (in practice at night, as a bit of energy is produced even when the sky is cloudy) you can withdraw from the network. Conversely when it produces too much it can use the network as an "accumulator". For this reason it is necessary to have two counters: one is used to calculate the energy produced by photovoltaic panels; the second counter, bidirectional, has the function to count the energy fed into the grid and that was withdrawn.

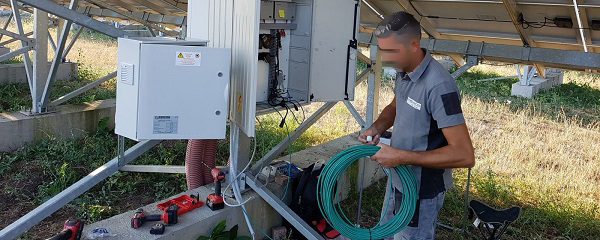

Design and installation

The installation of photovoltaic systems involves other favorable aspects, less direct but equally important:

- it takes away from future increases in the cost of energy (an average of 5% per annum);

- businesses can obtain tax relief;

- reduces emissions of greenhouse gases.

The intervention consists of the following phases.

- Preliminary survey at the site of installation.

- Elaboration of Feasibility Study and presentation of cost estimate to the client.

- Request to connect to the distribution network (TICA).

- Request authorization to the City Hall and possibly to the entities that put a constraint on the building (nature, landscape, etc...).

- Elaboration of the Executive Project.

- Dispatching of administrative formalities.

- System installation and verification of declaration of conformity Electric 37/08 (ex 46/90) release.

- Assistance under "Commissioning" (connection) by ENEL.

- Preparing documentation in order to obtain the incentives.

For the purposes of the choice, it is important to remember that according to the DM 37/08, every plant project must be drafted according to the rule of art, which is split in addition to existing legislation, including the indications of the guides and standards of UNI, of IEC and other standardization bodies belonging to the Member States of EU.

Maintenance

As a rule, a photovoltaic system works fully automatically and without failures for many years. Those who have a photovoltaic plant should verify its correct operation with special attention to the yield of the same.

In fact, in the case it falls short of expectations, we must investigate the reason and recognize if this is normal or whether it may be due to a malfunction. Economic losses caused by a malfunction that is protracted over time, could be considerable.

For these reasons, the inspection and maintenance of your photovoltaic system are especially important, as well as affordable. In fact, you can always count on a system developed in excellent condition and will ensure a more optimal performance resulting in a revenue loss. The signing of the maintenance contract also induces additional benefits. First of all that of always having a qualified reference point to which contact in case of malfunction or failure.

Production Verification

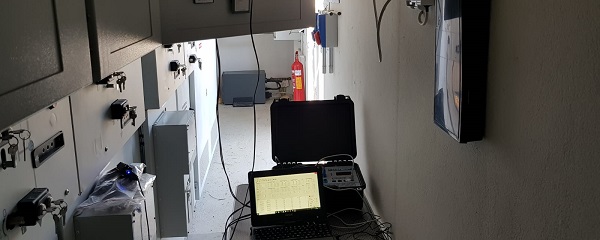

With the introduction of tariffs for the kilowatt-hour produced by photovoltaic systems, those who have invested in the construction of a plant have a strong economic interest that the plant functions properly. Therefore verification of performance plays a fundamental role. It typically includes the following phases:

- Monthly analysis of the production system.

The production plant is counted and can be read on a special display on the inverter or the data logger connected downstream. Data must also be related to weather conditions of the period considered, that can generate values deviate from expectations even if the system is fully functional. - Normalization of values.

We proceed to the normalization of data for comparison with those of other plants or with the values expected from the project. Although you can perform a monthly check, the most significant data is the annual production. The year in fact represents a complete cycle that allows a comparison with other systems with similar characteristics in addition to the statistical data. - Comparison with other data.

In addition to direct measurement it is also possible to proceed to the measurement data of the counter and compare them appropriately with other sources. In principle, what really matters is not the absolute value of the performance but that relative to other systems installed nearby. This fact allows you to figure out if a specific plant there are problems caused by faults or micro-inefficiencies that make the plant less productive. - Check disbursement of incentives.

The last, but not least, verification is the device analysis establishing fees that have been paid and which are being delivered to the facility. In particular, you may need to make a communication manual readings to the GSE for alignment, appropriate disbursement of incentives (particularly relevant for "large systems").